Fine Grind

Item Ref: QUAD-F10-1

- Manufacturer: Quadro

- Model: F10

FINE GRIND

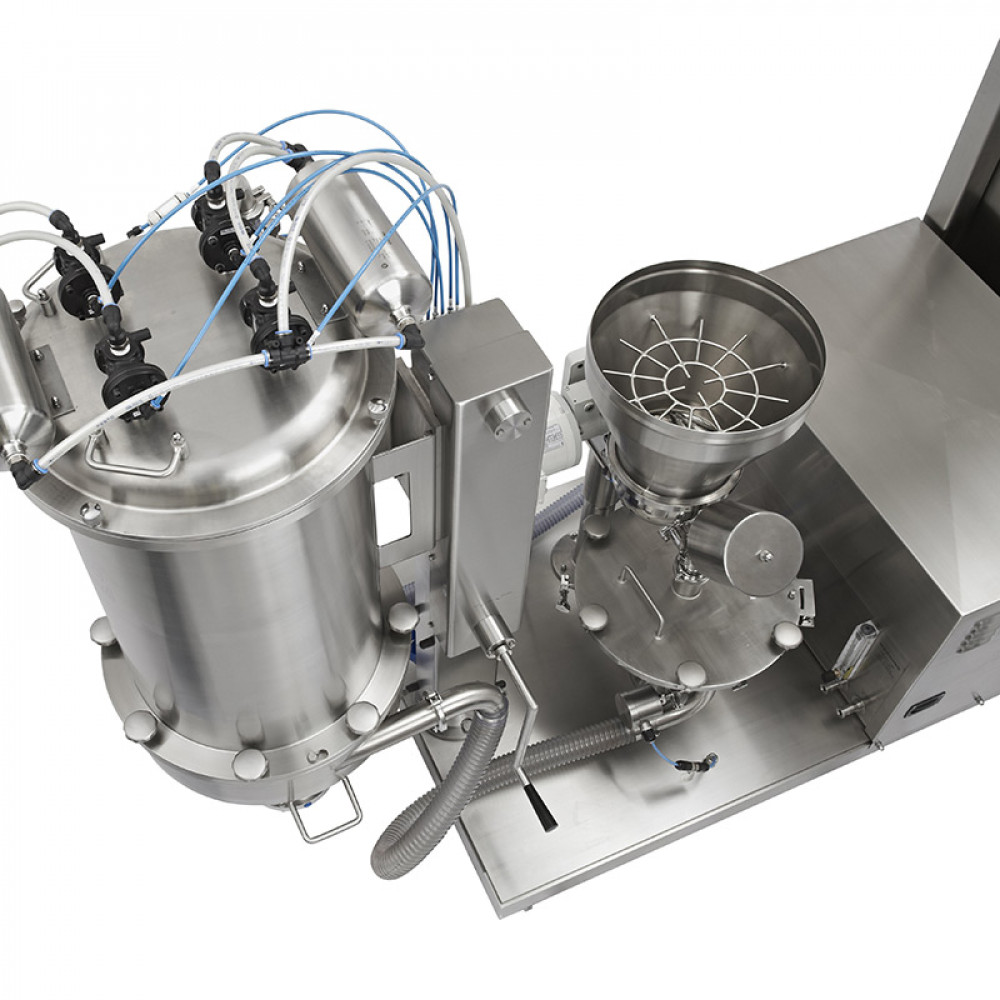

Superior product quality, unparalleled mobility, higher productivity, remarkably high yields (99.9+%), reduced waste, greater flexibility and enhanced control make the Fine Grind F10 a technological advancement among fine grinding and milling machines.

For d50 milling in the 5 – 45 micron (< 325 U.S. standard mesh) range, the Quadro® Fine Grind F10 delivers unsurpassed particle size consistency and maximum on-spec yield. Take fine grinding to a whole new level with the Fine Grind F10. Use Fine Grind F10 to size-reduce diverse materials — even materials traditionally considered difficult to grind. Examples include active pharmaceutical ingredients (APIs), excipients, fine chemicals,, nutraceuticals such as Lactoferrin, as well as high value flavors and fragrances.

In fact, Fine Grind F10 has been purposely designed and engineered to meet the exacting demands of milling APIs. This ultra fine grinding mill yields the highest percentage of fine particles within target of any fine mill technology. As in: 10% to 40% improvements compared to results from other milling options. Competing technologies — such as hammer mills, pin mills and jet mills — typically don’t incorporate two-stage size reduction technology like the Fine Grind, so they are simply not equipped to replicate Fine Grind’s supremely narrow particle size distribution (PSD) curves.

Fine Grind F10 is a turnkey, automated, stand-alone process system. Featuring a surprisingly compact footprint, convenient mobile design, and simple connection to existing collection devices, this fine powder grinder is the ideal addition to your production line when quick and efficient process integration is paramount. Even better, the exclusive all-in-one platform design of the F10 powder grinder mill eliminates the need for ancillary equipment. Appropriate for fine grinding applications ranging from APIs, to fine chemicals, cosmetics and foods.

BENEFITS

- Tight PSD (Particle Size Distribution) - Narrowest PSD curves for d90 targets in the 20 – 60 µm range.

- High Yield Rate - 99.9+% yield rate! What goes in, comes out, virtually eliminating waste and increasing profitability. Experience enhanced versatility, too. Available in an ATEX rated configuration and can be adapted for inert milling or cryogenic applications, for products with low melting temperatures and high ignition characteristics.

- PSD Control - Gives you the capability to control final PSDs with integrated variable-frequency drive, for responsive milling speed/torque adjustments based on the unique properties of your materials.

- Easy Cleaning & Maintenance - Switch from one product to another with minimal downtime; quickly disassembles in minutes to reduce the costs of labor and tooling replacements. Features sanitary GMP design. Other benefits include low heat production, reduced noise compared to other technologies, and significantly lower power/air consumption.

- Portability - Move from one processing location to another, with relative ease, to reduce the capital investment costs involved in owning, maintaining and operating redundant machines.

FEATURES

- Stainless steel construction throughout

- Accurate PSD (Particle Size Distribution) controllability

- Milling efficiencies ensure highest level of product on-spec (10% – 40% improvement over other fine milling technologies)

- Efficient product processing for nearly 100% product recovery

- All-in-one milling platform on portable base improves manufacturing flexibility and adaptability

TECHNICAL SPECIFICATIONS

- Model No. F10

- Capacities lb/h*: 10 – 500

- Capacities kg/h*: 4.5 – 230

- Approximate Dimensions (L x W x H) inches: 85 x 24 x 76

- Approximate Dimensions (L x W x H) mm: 2,160 x 610 x 1,930

- Power hp: 10

- Power kW: 7.5